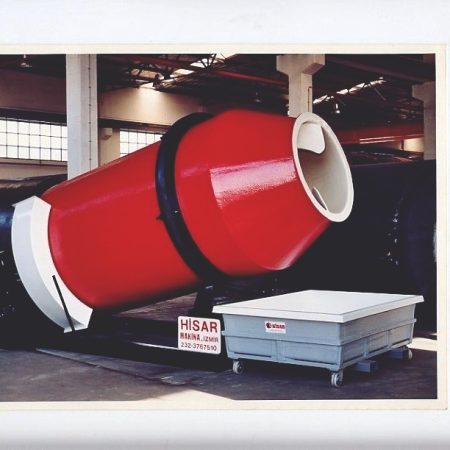

Polyester Mixer Drum Unit for casing industry.

– This collagen mixers are suitable for edible casing process. Inside surfaces of mixers made by certificated materials under food codex requirements.

– It can be used for:

– Mixing

– Salting

– Desalting

– Washing

– Chemical Operations

– Depending on the production type, technological requirements and your

demands, we will develop solutions together.

– We have achieved excellent results thanks to developments and innovations we

have made over many years.

– Different capacity options are available.

– Easy transportation and installation are provided by special designs.

– Main body produced by special type polyester.

Contact us for any further information.

Mixer Capacity: Mixer main body has 15 degrees angle between horizontal axes. With this inclination; it can be load up to mixer mouth level. We produce our polyester mixer in various capacities and sizes.

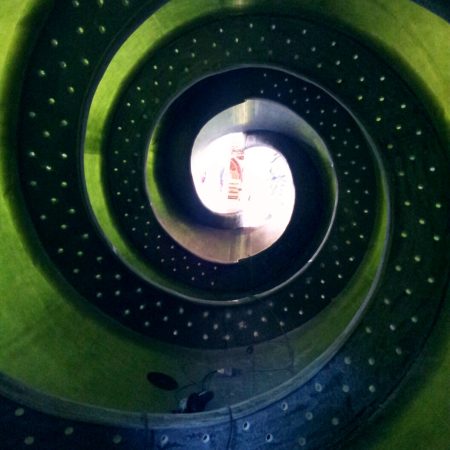

Mixer Body: Main body is an unyielding composite material made from homogeneous polyester mixture without any air gap. High security fiber layers quantity changes according to the capacity. In every stage of the main body production, it has turning operation which provides perfect balance. Main body inside spirals fixed to body with rivets which are hidden under fiber layers. Also spirals are completely made from polyester too.

Chassis: The chassis is made of IPN profile. To prevent corrosion, it is painted with primer and epoxy paint. Chassis; provides the integrity of rear and front legs which are made of steel sheet.

Ring: Mixer ring material is steel and ring housing is polyester material on main body. After ring is turned, connected to the housing with special production bolts.

Roller Bearings: Mixer balls are 2 pieces on the right and left. It is manufactured completely steel or tight-fitting kestamid material on steel shaft. Designed for heavy-duty conditions.

Main Body Housing: Steel main shaft rotation is providing by 2 pieces bearings which are placed in casting housing.

Body Sealing: Sealing is provided with gaskets and viton seals in the complete rear housing system, it’s designed by HISAR.

Piping / Circulation System: Piping system consist of stainless steel pipes, pump and valves. Pneumatic actuated valves can be used instead of manual valves.

Pump: Fluid take-off and circulation operations are provided by monopomp.

Filters and Drainage: Special manufacturing polyester filter with high strength values is located to bottom of mixer body inside. For making easy filter cleaning, there is a detachable cover at the middle. In addition, there is a discharging hole on the body, provides draining water.

Electrical Motor: Electrical motor power is determined by capacity. Selection is made from top productivity groups with the aim of saving energy.

Reducer: Reducer is heavy duty type, with legs and available for motor connection.

Rotation Speed: With Frequency (speed) Control Unit, Mixer speed is adjustable to any speed between 2 values determined by capacity.

Safety Equipments: Protecting equipments are mounted around rotating parts to ensure operator safety. In addition there are splash protectors placed at the same line of discharging hole.

Control Panel Equipments:

• Emergency Stop Button

• Power Switch

• Frequency (Speed) Control Unit

• Touch Control Panel (PLC)