Heating: The transfer oil in the air heating tank is heated with resistances. The air, circulated with fan motor, is heated and circulates when it passes through the tank.

Equipments:

1) Heating Tank

2) Resistance (Stainless Steel)

3) Manual Temperature Adjustment Switch

4) Air Bleeding Pipe

Dust Accumulation: There is a particulate trap inside the dust collection tank. Particles, inside the circulated air with fan motor, are caught by this trap. So clean air joins and continuous circulation.

Equipments:

1) Air Circulation Fan motor

2) Fan Beam

3) Accumulation Cyclone

Humidifying: Water inside the tank, is spouted to inside of drum from burner nozzle in planning gaps.

Equipments:

1) Humidity Entry Fitting

2) Selenoid Valve

3) Water Tank

4) Water Range Pipe

5) Water Entry Valve

Drum Capacity: Dry milling drum works with half volume and the rest is churning space as standard. Product quantity and chemical concentration changes by operators.

Main Body Material: Inside body material is completely stainless steel. This ensures smoothness surfaces. The internal wall of drum covered with glass wool for thermal insulation. . Complete body inner and outer sheets are AISI-316 quality stainless steel.

Shelves and Pegs: The shelves positioned across the inner surface of the drum. It is formed by the “V” shape of stainless steel sheets. There are 4 pieces shelves inside drum.

The pegs are made by suitable bending operations in our production, material is stainless steel, positioned between shelves

Loading / Unloading Door: Milling drum door material is AISI-316 quality stainless steel. It opens manually with turning of eccentric arms to down and up sides, sliding door to right and left sides. Sealing is provided by the pressure of the special production rubber (located on the door) to door frame by the eccentric clamping arms.

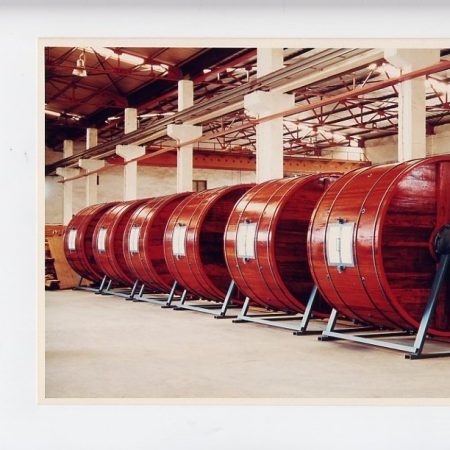

Chassis: Milling drum put on a solid, painted, steel construction. There is a safety barrier on the chassis.

Electrical Motor: In accordance with the capacity; 7,5kW electrical motor selection is made. The fan motor power is 1,5kW.

Reducer: Completely HISAR manufactured, open type reducer is used. Reducer makes transfer to main body with pulley and belts.

Pulley and Belts: Drum pulley consists of 6 parts and aluminum material. There are 3 belts on pulley.

Rotation Speed: Frequency (speed) control unit is used. It is possible to adjust speed between 5 to 16 rpm.

Bearing / Housing: There are rolling bearings used. Bearings are heavy duty type spherical roller.

Brake: Special manufacturing pneumatic brake is used. It allows to stop drum in the desired position.

Soft Start: The soft-start function of drum is provided with frequency control unit. Soft-start prevents knock start and overloading of motor.

Control Panel: Control panel is produced according to IP65 protection and safety standards. Time, temperature and loop adjustments can be made through the panel.