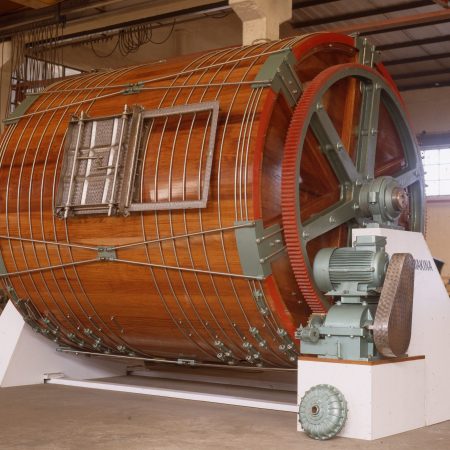

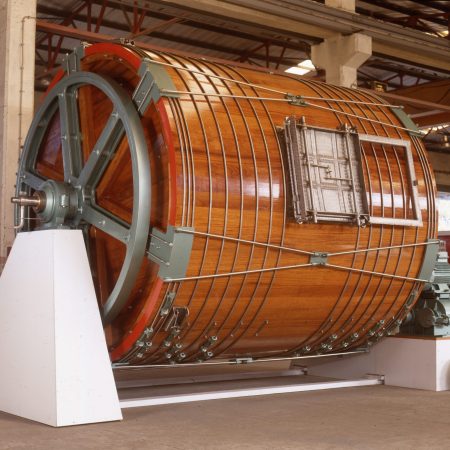

Main Body Features: The woods “used in production of drum” are imported from West Africa and they are highly resistant to chemicals. At production; hard, baked and dehumidified woods are used. Thus provides, more durable main body. Main body woods are angled, according to drum’s diameter. It is for exact connection. Round, Bottom and Cross woods thickness are determined under iroko drum’s dimensions.

Pegs: Peg’s material is polypropylene. Quantity changes according by the drum’s diameter.

Inside Filters: Filter’s material is special manufactured polypropylene which has resistant to acid and chemicals.

Rotation Speed: Suitable rotation speed choose according to drum’s sizes and production type. Traditionally, drum has two-speed. With customers demand, it can be set to any speed between two specified values with used Frequency (Speed) Control Unit.

Main (Crown) Gear: Main (Crown) gear’s material is casting steel. After turning operation in our production, teeth are opened in our gear hobbling machine.

Pinion Gear: Pinion gear’s material is special alloy bronze.

Arm Cross: Arm cross choose from between “6 arm cross type” or “without teeth crown gear model type” according to drum’s diameter.

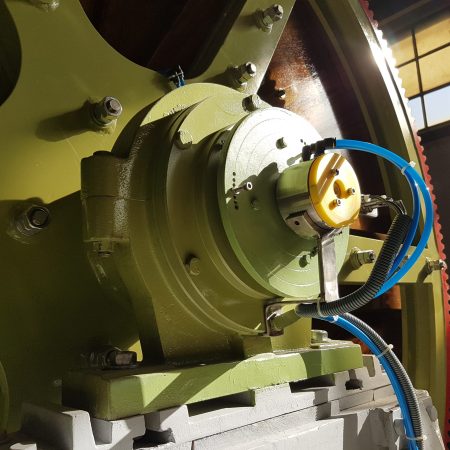

Bearing / Housing: Heavy duty type spherical bearing is used. Housing’s material is GG26 quality casting.

Electrical Motor: If drum has Frequency (Speed) control unit; one-speed; otherwise two-speed electrical motor selection is made. For saving electricity, electric motor is choose from top efficiency groups, with suitable power supply. It has cast body and special protection.

Reducer: Totally HISAR production; 3-axis, horizontal, heavy duty type reducer is used.

Loading / Unloading Door: Loading-unloading door’s material is AISI-316 quality stainless steel. Doors opens and closes manually with turning eccentric arms to right-left sides and sliding door. Special manufactured rubber, which located upper side of door, provides leak proofing with pressing to door frame.

Drainage Valves: Drainage valve’s material is AISI-316 quality stainless steel. Fluid drainage is provided by opening eccentric arms and leak proofing is provided with special manufactured seals.

Hoops: Hoop’s material is galvanized hot drawing structural steel. It provides integrity to drum. Hoops connection is made with tie rods.

Brake: Brake is special production and pneumatic type. It allows to stop drum in desired position.

Soft Start: Drums which have frequency control unit, do not need any other soft-start equipment. Frequency control unit fulfill this function. Otherwise, soft-start function is provided with hydraulic coupling. Soft-start prevents knock start and overloading of motor.

Electrical Control Panel Equipments:

- Timer

- Start-Stop Buttons

- Fast-Slow Switch

- Emergency Stop Button

- Forward-Stop-Back Switch

- Automatic-Manual Switch

- Optionally Frequency Control Unit

- Optionally Touch (PLC) Screen